-

×

VagaFX Academy Course with VAGAFX

1 × $41.00

VagaFX Academy Course with VAGAFX

1 × $41.00 -

×

KvngSolz Fx Mentorship

1 × $27.00

KvngSolz Fx Mentorship

1 × $27.00 -

×

Turtle Soup Course with ICT Trader Romeo

1 × $5.00

Turtle Soup Course with ICT Trader Romeo

1 × $5.00 -

×

Options Trading & Ultimate MasterClass With Tyrone Abela - FX Evolution

1 × $54.00

Options Trading & Ultimate MasterClass With Tyrone Abela - FX Evolution

1 × $54.00 -

×

The Secrets to Successful Forex Trading 2004

1 × $6.00

The Secrets to Successful Forex Trading 2004

1 × $6.00 -

×

Bollinger Bands Trading Strategies That Work

1 × $6.00

Bollinger Bands Trading Strategies That Work

1 × $6.00 -

×

Butterfly and Condor Workshop with Aeromir

1 × $15.00

Butterfly and Condor Workshop with Aeromir

1 × $15.00 -

×

The ETF Handbook, + website: How to Value and Trade Exchange Traded Funds (1st Edition) with David Abner

1 × $6.00

The ETF Handbook, + website: How to Value and Trade Exchange Traded Funds (1st Edition) with David Abner

1 × $6.00 -

×

Ninja Order Flow Trader (NOFT)

1 × $39.00

Ninja Order Flow Trader (NOFT)

1 × $39.00 -

×

The Prop Trading Code with Brannigan Barrett - Axia Futures

1 × $23.00

The Prop Trading Code with Brannigan Barrett - Axia Futures

1 × $23.00 -

×

The Naked Eye: Raw Data Analytics with Edgar Torres - Raw Data Analytics

1 × $8.00

The Naked Eye: Raw Data Analytics with Edgar Torres - Raw Data Analytics

1 × $8.00 -

×

Trading Psychology Mastery Course - Trading Composure

1 × $6.00

Trading Psychology Mastery Course - Trading Composure

1 × $6.00 -

×

Crypto Trading Academy with Cheeky Investor - Aussie Day Trader

1 × $13.00

Crypto Trading Academy with Cheeky Investor - Aussie Day Trader

1 × $13.00 -

×

Tutorials in Applied Technical Analysis with Daryl Guppy

1 × $4.00

Tutorials in Applied Technical Analysis with Daryl Guppy

1 × $4.00 -

×

Trading Framework with Retail Capital

1 × $24.00

Trading Framework with Retail Capital

1 × $24.00 -

×

Ultimate Trading Course with Dodgy's Dungeon

1 × $8.00

Ultimate Trading Course with Dodgy's Dungeon

1 × $8.00 -

×

Don Fishback ODDS The Key to 95 Winners

1 × $6.00

Don Fishback ODDS The Key to 95 Winners

1 × $6.00 -

×

The Scalper’s Boot Camp (Sep 2011)

1 × $23.00

The Scalper’s Boot Camp (Sep 2011)

1 × $23.00 -

×

The Trading Blueprint with Brad Goh - The Trading Geek

1 × $5.00

The Trading Blueprint with Brad Goh - The Trading Geek

1 × $5.00 -

×

The Encyclopedia Trading Strategies

1 × $6.00

The Encyclopedia Trading Strategies

1 × $6.00 -

×

WondaFX Signature Strategy with WondaFX

1 × $5.00

WondaFX Signature Strategy with WondaFX

1 × $5.00 -

×

Advanced Spread Trading with Guy Bower - MasterClass Trader

1 × $15.00

Advanced Spread Trading with Guy Bower - MasterClass Trader

1 × $15.00 -

×

The Orderflows Trade Opportunities Encyclopedia with Michael Valtos

1 × $8.00

The Orderflows Trade Opportunities Encyclopedia with Michael Valtos

1 × $8.00 -

×

The Orderflow Masterclass with PrimeTrading

1 × $17.00

The Orderflow Masterclass with PrimeTrading

1 × $17.00 -

×

Yuri Shamenko Videos

1 × $5.00

Yuri Shamenko Videos

1 × $5.00 -

×

Best of the Best: Collars with Amy Meissner & Scott Ruble

1 × $15.00

Best of the Best: Collars with Amy Meissner & Scott Ruble

1 × $15.00 -

×

Forex Mentor Seminar with Peter Bain

1 × $6.00

Forex Mentor Seminar with Peter Bain

1 × $6.00 -

×

TRADING NFX Course with Andrew NFX

1 × $5.00

TRADING NFX Course with Andrew NFX

1 × $5.00 -

×

Understanding Spreads with Edward Dobson & Roger Reimer

1 × $6.00

Understanding Spreads with Edward Dobson & Roger Reimer

1 × $6.00 -

×

Forecast 2024 Clarification with Larry Williams

1 × $15.00

Forecast 2024 Clarification with Larry Williams

1 × $15.00 -

×

Ultimate Options Trading Blueprint

1 × $23.00

Ultimate Options Trading Blueprint

1 × $23.00 -

×

Scalp Strategy and Flipping Small Accounts with Opes Trading Group

1 × $5.00

Scalp Strategy and Flipping Small Accounts with Opes Trading Group

1 × $5.00 -

×

The Forex Trading Course: A Self-Study Guide To Becoming a Successful Currency Trader with Abe Cofnas

1 × $6.00

The Forex Trading Course: A Self-Study Guide To Becoming a Successful Currency Trader with Abe Cofnas

1 × $6.00 -

×

Advanced Guide to How SimplerOptions Uses ThinkorSwim (274 Minutes) with Henry Gambell

1 × $15.00

Advanced Guide to How SimplerOptions Uses ThinkorSwim (274 Minutes) with Henry Gambell

1 × $15.00 -

×

High Probability Trading Using Elliott Wave And Fibonacci Analysis withVic Patel - Forex Training Group

1 × $10.00

High Probability Trading Using Elliott Wave And Fibonacci Analysis withVic Patel - Forex Training Group

1 × $10.00 -

×

Bond Market Course with The Macro Compass

1 × $15.00

Bond Market Course with The Macro Compass

1 × $15.00 -

×

TTM Slingshot & Value Charts Indicators

1 × $6.00

TTM Slingshot & Value Charts Indicators

1 × $6.00 -

×

White Phoenix’s The Smart (Money) Approach to Trading with Jayson Casper

1 × $39.00

White Phoenix’s The Smart (Money) Approach to Trading with Jayson Casper

1 × $39.00 -

×

The Ultimate Professional Trader Plus CD Library

1 × $31.00

The Ultimate Professional Trader Plus CD Library

1 × $31.00 -

×

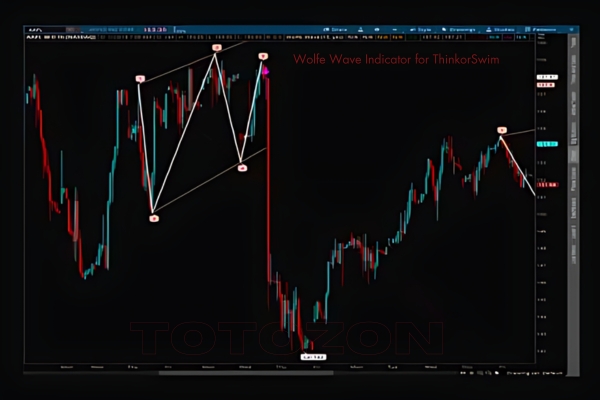

Wolfe Wave Indicator for ThinkorSwim

1 × $6.00

Wolfe Wave Indicator for ThinkorSwim

1 × $6.00 -

×

The Indices Orderflow Masterclass with The Forex Scalpers

1 × $23.00

The Indices Orderflow Masterclass with The Forex Scalpers

1 × $23.00 -

×

Level 3 - AlgoX Trading Tactics

1 × $31.00

Level 3 - AlgoX Trading Tactics

1 × $31.00 -

×

TTM Slingshot

1 × $6.00

TTM Slingshot

1 × $6.00 -

×

Trading Patterns for Producing Huge Profits with Barry Burns

1 × $4.00

Trading Patterns for Producing Huge Profits with Barry Burns

1 × $4.00 -

×

W. D Gann 's Square Of 9 Applied To Modern Markets with Sean Avidar - Hexatrade350

1 × $23.00

W. D Gann 's Square Of 9 Applied To Modern Markets with Sean Avidar - Hexatrade350

1 × $23.00 -

×

The FOREX Blueprint with The Swag Academy

1 × $5.00

The FOREX Blueprint with The Swag Academy

1 × $5.00 -

×

XJO Quant - High Probability Trading Setups on ASX 200 Index

1 × $31.00

XJO Quant - High Probability Trading Setups on ASX 200 Index

1 × $31.00 -

×

DayTradeMax

1 × $31.00

DayTradeMax

1 × $31.00 -

×

The W.D. Gann Method of Trading with Gerald Marisch

1 × $6.00

The W.D. Gann Method of Trading with Gerald Marisch

1 × $6.00 -

×

$20 – 52k 20 pips a day challange with Rafał Zuchowicz - TopMasterTrader

1 × $5.00

$20 – 52k 20 pips a day challange with Rafał Zuchowicz - TopMasterTrader

1 × $5.00 -

×

Voodoo Lines Indicator

1 × $62.00

Voodoo Lines Indicator

1 × $62.00 -

×

Kaizen Pipsology: Forex Mentorship

1 × $8.00

Kaizen Pipsology: Forex Mentorship

1 × $8.00 -

×

The Ed Ponsi Forex Playbook: Strategies and Trade Set-Ups with Ed Ponsi

1 × $6.00

The Ed Ponsi Forex Playbook: Strategies and Trade Set-Ups with Ed Ponsi

1 × $6.00 -

×

0 DTE Options Trading Workshop with Aeromir Corporation

1 × $15.00

0 DTE Options Trading Workshop with Aeromir Corporation

1 × $15.00 -

×

Unlocking the Profits of the New Swing Chart Method with Dave Reif & Jeff Cooper

1 × $23.00

Unlocking the Profits of the New Swing Chart Method with Dave Reif & Jeff Cooper

1 × $23.00 -

×

The Complete Guide to Multiple Time Frame Analysis & Reading Price Action with Aiman Almansoori

1 × $13.00

The Complete Guide to Multiple Time Frame Analysis & Reading Price Action with Aiman Almansoori

1 × $13.00 -

×

Options Trading Business with The Daytrading Room

1 × $23.00

Options Trading Business with The Daytrading Room

1 × $23.00 -

×

Tradingology Complete Options Course with David Vallieres

1 × $6.00

Tradingology Complete Options Course with David Vallieres

1 × $6.00 -

×

Twelve Ways to Survive the Next Twelve Months with Adam Lass

1 × $6.00

Twelve Ways to Survive the Next Twelve Months with Adam Lass

1 × $6.00 -

×

The Basics of Swing Trading with Jason Bond

1 × $31.00

The Basics of Swing Trading with Jason Bond

1 × $31.00 -

×

TTM Bricks, Trend & BB Squeeze for TS

1 × $6.00

TTM Bricks, Trend & BB Squeeze for TS

1 × $6.00 -

×

The Folio Management Phenomenon with Gene Walden

1 × $6.00

The Folio Management Phenomenon with Gene Walden

1 × $6.00 -

×

ICT Prodigy Trading Course – $650K in Payouts with Alex Solignani

1 × $15.00

ICT Prodigy Trading Course – $650K in Payouts with Alex Solignani

1 × $15.00 -

×

Compass Trading System with Right Line Trading

1 × $39.00

Compass Trading System with Right Line Trading

1 × $39.00 -

×

Trading Short TermSame Day Trades Sep 2023 with Dan Sheridan & Mark Fenton - Sheridan Options Mentoring

1 × $31.00

Trading Short TermSame Day Trades Sep 2023 with Dan Sheridan & Mark Fenton - Sheridan Options Mentoring

1 × $31.00 -

×

Options Trading RD3 Webinar Series

1 × $31.00

Options Trading RD3 Webinar Series

1 × $31.00 -

×

Time by Degrees Online Coaching 2009 + PDF Workbooks

1 × $54.00

Time by Degrees Online Coaching 2009 + PDF Workbooks

1 × $54.00 -

×

Market Profile Trading Strategies Webinar with Daniel Gramza

1 × $4.00

Market Profile Trading Strategies Webinar with Daniel Gramza

1 × $4.00 -

×

With All Odds Forex System I & II with Barry Thornton

1 × $6.00

With All Odds Forex System I & II with Barry Thornton

1 × $6.00 -

×

Winning Market Systems. 83 Ways to Beat the Market

1 × $6.00

Winning Market Systems. 83 Ways to Beat the Market

1 × $6.00

Design for Six Sigma with Subir Chowdhury

$6.00

File Size: Coming soon!

Delivery Time: 1–12 hours

Media Type: Online Course

Content Proof: Watch Here!

You may check content proof of “Design for Six Sigma with Subir Chowdhury” below:

Design for Six Sigma with Subir Chowdhury

Introduction

Design for Six Sigma (DFSS) is a powerful methodology that integrates the principles of Six Sigma into the design and development process. Subir Chowdhury, a leading expert in quality management, has extensively explored and articulated the benefits of DFSS. In this article, we delve into the core concepts of DFSS, its significance, and practical strategies for implementation.

Understanding Design for Six Sigma

What is Design for Six Sigma?

Design for Six Sigma (DFSS) is a systematic approach that aims to design products and processes that meet customer expectations and achieve high levels of quality from the outset. It integrates Six Sigma principles into the design phase, ensuring that potential issues are identified and addressed early.

The Importance of DFSS

Implementing DFSS helps organizations to create robust products and services that meet customer needs, reduce defects, and improve overall quality. This proactive approach can lead to significant cost savings and enhanced customer satisfaction.

Key Components of DFSS

Define

The first phase involves defining the project goals, customer requirements, and the scope of the project. Clear definition sets the foundation for successful implementation.

Measure

In this phase, we measure and collect data on current processes and identify areas for improvement. This helps in understanding the baseline performance.

Analyze

Analyzing the data collected helps in identifying root causes of defects and areas where improvements are needed. This phase is crucial for developing effective solutions.

Design

The design phase involves creating and testing potential solutions. It includes developing prototypes and simulations to ensure the design meets quality standards.

Verify

Verification ensures that the design meets customer requirements and performance standards. It involves rigorous testing and validation of the final design.

Benefits of Implementing DFSS

Enhanced Product Quality

DFSS focuses on designing quality into the product from the beginning, reducing the likelihood of defects and ensuring high performance.

Cost Reduction

By identifying and addressing potential issues early, DFSS helps in reducing costs associated with rework, scrap, and warranty claims.

Increased Customer Satisfaction

Delivering high-quality products that meet customer needs leads to increased customer satisfaction and loyalty.

Competitive Advantage

Organizations that implement DFSS can gain a competitive edge by consistently delivering superior products and services.

Practical Strategies for DFSS Implementation

Involve Cross-Functional Teams

Involving cross-functional teams ensures that diverse perspectives are considered, leading to more comprehensive solutions.

Utilize Advanced Tools and Techniques

DFSS leverages advanced tools such as Quality Function Deployment (QFD), Failure Modes and Effects Analysis (FMEA), and Design of Experiments (DOE) to achieve high-quality designs.

Continuous Training and Development

Providing continuous training and development opportunities for employees ensures they have the necessary skills and knowledge to implement DFSS effectively.

Foster a Culture of Quality

Creating a culture that prioritizes quality and continuous improvement is essential for the successful implementation of DFSS.

Case Studies: Successful DFSS Implementation

Case Study 1: Automotive Industry

In the automotive industry, DFSS has been instrumental in designing vehicles that meet stringent safety and performance standards. Companies have successfully used DFSS to reduce defects and improve customer satisfaction.

Case Study 2: Healthcare Sector

In healthcare, DFSS has been used to design medical devices and processes that enhance patient safety and care. The methodology has helped in reducing errors and improving outcomes.

Case Study 3: Electronics Manufacturing

Electronics manufacturers have implemented DFSS to design products that meet high-quality standards and customer expectations. This has led to reduced defects and increased market share.

Challenges in DFSS Implementation

Resistance to Change

Resistance to change can hinder the successful implementation of DFSS. Overcoming this requires effective communication and leadership.

Complexity of Tools

The advanced tools and techniques used in DFSS can be complex and require specialized training. Ensuring employees are adequately trained is crucial.

Resource Constraints

Implementing DFSS can be resource-intensive. Organizations need to allocate sufficient resources to ensure successful implementation.

Overcoming Implementation Challenges

Leadership Commitment

Strong leadership commitment is essential to drive DFSS implementation and overcome resistance to change.

Comprehensive Training Programs

Offering comprehensive training programs can help employees understand and effectively use DFSS tools and techniques.

Effective Resource Management

Effective resource management ensures that the necessary resources are available for successful DFSS implementation.

Conclusion

Design for Six Sigma (DFSS) is a transformative approach that integrates Six Sigma principles into the design and development process. By focusing on quality from the outset, DFSS helps organizations create superior products and services, reduce costs, and enhance customer satisfaction. Subir Chowdhury’s insights and strategies provide a valuable roadmap for successful DFSS implementation.

FAQs

1. What is the main goal of Design for Six Sigma?

The main goal of DFSS is to design products and processes that meet customer expectations and achieve high levels of quality from the beginning.

2. How does DFSS differ from traditional Six Sigma?

DFSS focuses on the design and development phase, while traditional Six Sigma primarily addresses process improvement in existing operations.

3. What are some common tools used in DFSS?

Common tools used in DFSS include Quality Function Deployment (QFD), Failure Modes and Effects Analysis (FMEA), and Design of Experiments (DOE).

4. Can DFSS be applied in all industries?

Yes, DFSS can be applied across various industries, including manufacturing, healthcare, automotive, and electronics.

5. What are the benefits of involving cross-functional teams in DFSS?

Involving cross-functional teams ensures diverse perspectives, leading to more comprehensive and effective solutions.

Be the first to review “Design for Six Sigma with Subir Chowdhury” Cancel reply

You must be logged in to post a review.

Related products

Forex Trading

Forex Trading

Forex Trading

Forex Trading

Forex Trading

Forex Trading

Forex Trading

Forex Trading

Forex Trading

Reviews

There are no reviews yet.